CPQ for Manufacturing: How to Make Big Reductions in Operational Costs

The manufacturing quoting process is notoriously clunky and there are a lot of moving parts.

From manual calculations to constant back-and-forth emails, even the tiniest of delays can ripple through your entire operation, impacting production timelines, customer satisfaction, and ultimately, your bottom line.

This is where CPQ (Configure, Price, Quote) software comes in. With it, you can generate accurate, tailored quotes in minutes and automate the complex pricing models that are most prevalent in the manufacturing industry.

So, if your quoting process is slowing down the rest of your workflow, it might be time to switch things up. Here’s how to do that with CPQ.

What is CPQ in Manufacturing?

CPQ is software that automates and simplifies the often-complex quoting process. It automatically configures products, calculates prices, and generates quotes all from the same system.

There are three key components of CPQ for manufacturing:

1. Configure

Manufacturing often involves intricate product configurations, like custom sizes, materials, or features. CPQ tools let you build rules and logic into the system so every configuration is technically viable and ties into what you can actually produce.

2. Price

If you’re in manufacturing, you’re well-versed in fluctuating material costs, tiered discounts, and other fun things that impact your margins. CPQ makes sure your prices are accurate by automatically factoring in current costs, discounts, and profitability thresholds. It can also tweak quotes to reflect bulk orders and customer loyalty levels.

3. Quote

At the end of the process, you have the actual quote. This is often the biggest bottleneck, but CPQ software automatically creates quotes based on your configurations and pricing rules. It basically pulls everything together into a professional, customer-ready quote.

Why Manufacturing Businesses Need CPQ Solutions

If you’ve been using good old spreadsheets and emails to create quotes, you’re probably no stranger to the pain points.

- Long quote-to-cash cycles. When it takes days (or weeks!) to finalize a quote, you risk losing deals to competitors who can deliver faster.

- Inconsistent pricing and discounting. Relying on spreadsheets and disparate systems makes it near-on impossible to standardize pricing acoss products and regions.

- Lack of visibility and reporting. Without clear data, it’s hard to identify bottlenecks and forecast revenue.

Let’s talk about how CPQ solutions tackle these problems.

For starters, CPQ shortens sales cycles by automating the quoting process. Instead of taking days and a mind-numbing amount of back-and-forths, you can generate precise quotes in minutes. This keeps deals moving and frees up your sales team so they can focus on actually closing. In fact, CPQ can reduce sales cycle times by up to 25%.

CPQ also minimizes errors. Built-in logic makes sure every quote follows your pricing rules, any discount policies, and your product configurations. And, if you have complex product lines, CPQ is scalable. It adapts to your needs and can handle the most intricate configurations, even if you’re quoting custom builds or high-volume orders.

Core Functionalities of CPQ Software for Manufacturing

CPQ should make your job easier. Here are the key functionalities you should look for to make sure the software you choose fits your business needs.

Managing Complex Product Configurations

Custom products are a staple in manufacturing, but manually juggling complex configurations is time-consuming and prone to error. CPQ simplifies this integral but fiddly bit of the job with customization rules that make sure every product you quote can actually be built and that they meet the customer’s needs.

There’s nothing more wince-incuding than quoting for a product that isn’t actually possible.

To add to this, advanced CPQ tools often have advanced tools—the clue is in the name—like 3D product configurators, that let you visualize designs in real-time, and dynamic bill of materials (BOM) creation so teams have the right specs from the start.

Dynamic Pricing Mechanisms

Pricing is rarely static in manufacturing. You’re often up against material costs, labor rates, and production rates that change on an almost daily basis, which can make it incredibly tricky to pin down a price.

CPQ software uses real-time pricing updates to account for these variables so your quotes are always accurate and based on the most current costs.

Automated Guided Selling

Sometimes the hardest part of selling is matching a product to a customer’s requirements. Luckily, CPQ software helps your sales reps recommend the best products and configurations for the circumstances. This means they’re always suggesting the right solution at the right price, regardless of how complex your product catalog is.

Approval and Workflow Automation

Long approval processes can often be the death of deals—or, at the very least, can derail them. CPQ tools remove the most common bottlenecks by automating repetitive, mandatory workflows. For example, quotes can be automatically routed to the right people for quick review or approval.

Integration with ERP, CRM, and CAD Systems

One of CPQ’s biggest strengths is the way it can satisfyingly integrate with your existing systems. Whether it’s pulling customer data from your CRM, syncing production details from your ERP, or importing designs from CAD software, CPQ acts as a central hub that brings together all your most used and necessary tools.

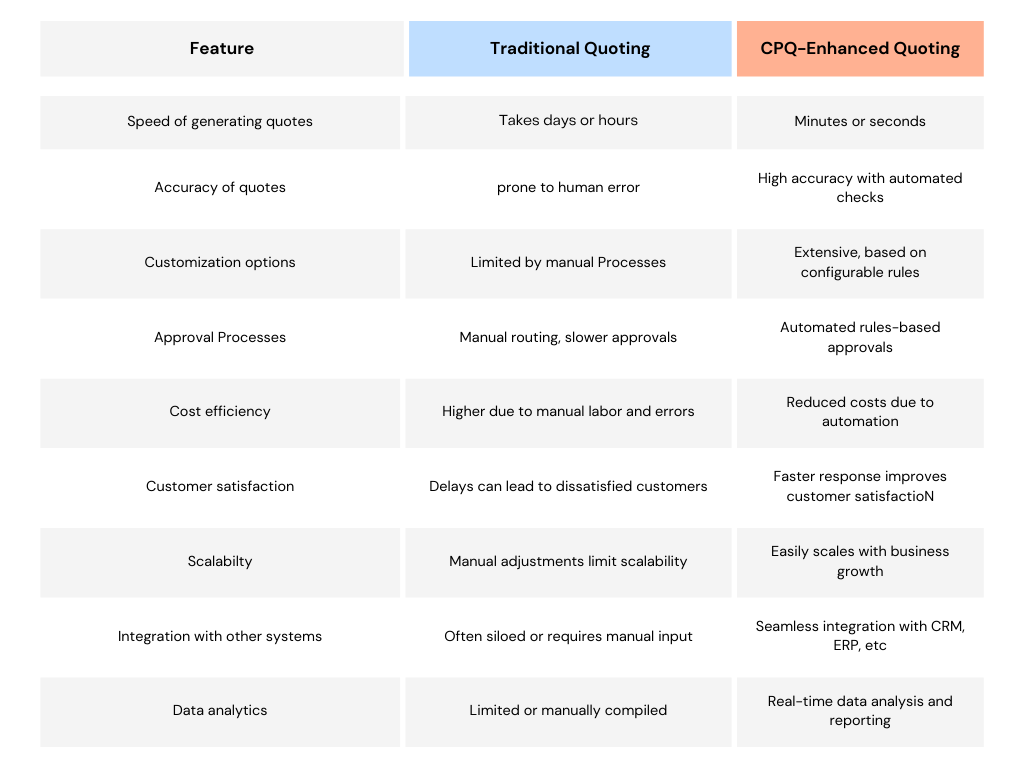

Traditional Quoting vs. CPQ-Enhanced Quoting Process

We’ve put together this handy table so you can compare the traditional quoting process and a CPQ-enhanced quoting process side-by-side.

Why CPQ Stands Out

CPQ reduces operational costs because you can automate repetitive tasks and need fewer hands on deck. This, paired with powerful automated workflows and instant pricing calculations means you can deliver quick, accurate quotes—and who doesn’t love a quick, accurate quote? Your customers definitely do. Because that’s another thing—CPQ improves the overall customer experience by tailoring quotes based on a client’s unique situation.

The Key Benefits of CPQ for Manufacturing

Let’s break this down.

Faster Quote-to-Cash Cycles

Look, we all know that time is money in manufacturing and traditional quotes just don’t cut it when they can take days to deliver. CPQ slashes the amount of time it takes to generate quotes by automating the whole process. Pre-set rules and templates mean you can fire off accurate, customer-ready quotes in literal minutes.

Increased Accuracy and Reduced Errors

Manual quoting leaves far too much room for error. CPQ eliminates potential errors and miscalculations by automating pricing rules and product configurations (even really complex ones). Plus, every quote is automatically checked against your predefined rules to make sure it’s accurate.

Scalability and Flexibility

The quoting process can become totally overwhelming as your business grows. But regardless of whether you’re adding new products, exploring new markets, or juggling more complex orders, CPQ can handle it with no fuss.

Improved Customer Responsiveness

The fast quote generation has a knock-on effect—you can respond to inquiries within hours instead of days, which makes a huge difference in competitive markets. The accuracy and customization capabilities also show your customers you understand their needs and can deliver exactly what they want.

Cost Efficiency

Beyond speeding up processes, CPQ saves you money by reducing the amount of manual work and admin overhead needed to send off quotes. Automating repetitive but necessary tasks frees up your team to focus on more strategic activities, like building relationships with customers or closing bigger deals.

2 Real-World Applications of CPQ in Manufacturing

Here’s how two very real manufacturing brands have used CPQ to speed up processes, save costs, and improve customer experience.

Case Study #1: How Howden Netherlands Slashed Time-to-Quote by 83%

Howden Netherlands, a pioneer in industrial cooling fans with over 60 years of experience, completely changed its sales process by implementing Experlogix CPQ.

Known for its ultra-low noise applications and tailored solutions for industries like power, oil and gas, and petrochemicals, Howden struggled with the manual quoting processes which often led to costly order errors.

By adopting CPQ, the company eliminated misunderstandings between their team and customers, making sure products consistently met client expectations.

The impact has been remarkable. Pricing time for orders has been slashed by 83%, significantly improving efficiency and freeing up resources for other critical tasks.

Case Study #2: How Freedom Concepts Used CPQ Software to Quickly Quote Customized Products

Freedom Concepts, a leader in adaptive bikes and seating solutions for individuals with disabilities turned to Experlogix CPQ to handle its highly customized product offerings.

The solution has saved the organization dozens of hours by removing the need to recreate quotes all while giving engineers a way to easily update configuration rules as needs evolve. Plus, the integration with Microsoft Dynamics means accurate data can flow freely between systems.

The company plans to extend CPQ functionality to its dealer network to simplify the sales process across channels. Since adopting Experlogix, Freedom Concepts has enjoyed far more reliable quotes—something that’s been a critical factor in maintaining its high level of customer service.

How to Overcome Common CPQ Implementation Challenges

Here are the most common CPQ challenges and how to tackle them.

Challenge #1: Understanding Organizational Needs

Before you go ahead and actually implement CPQ, you need to figure out where it’ll make the biggest difference. To do this, it’s worth taking a close look at your current processes:

- Where are the bottlenecks?

- Are manual workflows slowing down your quote-to-cash cycle? If so, where?

- Is pricing inconsistency causing revenue leaks?

Understanding these points of weakness will help you deploy CPQ in such a way that it’ll have the most immediate and noticeable impact.

Challenge #2: Integration with Existing Systems

A successful CPQ rollout doesn’t happen in a vacuum. In fact, without integrating it with your ERP, CRM, and CAD systems, you risk creating brand new silos—the absolute opposite of what it should be doing. Avoid this by looking for a CPQ solution with pre-built connectors or solid APIs so you can easily share data across platforms.

You ideally want your CPQ to integrate with your ERP solution so you can sync quotes with your inventory, and you want it to work closely with your CRM to give sales teams quick access to customer history.

Challenge #3: Training and Change Management

Teams that are used to spreadsheets and emails need time and guidance to adjust to a new system. One of the hardest changes can be getting your team to not just learn how to use a CPQ system, but to figure out how they can thrive with it.

Start by involving key stakeholders early to get buy-in and build excitement. You can then offer training sessions to walk reps through the most common and inspiring use cases.

Challenge #4: Data Accuracy and Maintenance

CPQ is only as good as the data fed into it. Before you implement a new system, run a full data audit to clean up and standardize your existing data and inputs. Then, follow on from this by creating processes for ongoing maintenance, like regular reviews of pricing updates.

Best Practices for Successful CPQ Adoption in Manufacturing

When done right, CPQ adoption and implementation should be relatively pain-free. Here’s how to make it go as smoothly as possible.

- Assess your current quoting process. Map out every step and identify where delays, errors, or inefficiencies are happening.

- Choose the right CPQ vendor. Look for features like guided selling, dynamic pricing, and robust analytics. If it helps, ask vendors about their experience with manufacturing companies and see if they have any relevant case studies they can share.

- Pilot testing. Start small—choose a pilot project that represents a typical use case for your quoting process. Use this opportunity to refine your configurations, workflows, and integrations. Then, gather feedback and make adjustments before rolling it out across the rest of your org.

- Continuous optimization. Schedule regular reviews of your pricing rules, product configurations, and workflows to make sure they still align with your goals. Use analytics to track performance and identify any areas for improvement.

Future Trends in CPQ for Manufacturing

What does the future of CPQ for manufacturing look like?

We’ll see more AI and machine learning capabilities which will be able to analyze historical sales and market trends to recommend the right pricing strategies. This technology will also allow you to learn from past quotes to craft highly tailored proposals for specific customers.

And, as manufacturers embrace digital transformation, cloud-based CPQ solutions are becoming the norm—particularly for global teams and those with distributed sales depts.

There will also be a shift in customer expectations. Today, people increasingly want speed, accuracy, and personalization, and these three needs aren’t going anywhere soon. Fast, accurate CPQ tools will tackle this head-on by dramatically speeding up the whole process.

Finally, we’ll see more manufacturers using 3D visualization tools to add another layer to the quoting experience. Customers will be able to see a virtual representation of their configured product in real time, whether it’s a piece of machinery or a custom part.

From Quote-to-Cash in Minutes

The long-term benefits of CPQ are clear. It saves time, improves accuracy, and scales with you as your business grows, but on a more granular level, it accelerates the quote-to-cash cycle and removes costly, human errors.

Ready to transform your manufacturing quoting process? Schedule a demo today to see how Experlogix CPQ can drive profitability and efficiency in your business.

CPQ in Manufacturing FAQ

CPQ (Configure, Price, Quote) in manufacturing is software that helps businesses configure complex products, accurately price them based on rules, and quickly generate quotes. It streamlines sales processes, ensuring accurate customization and pricing for customer-specific requirements.

CPQ reduces manual errors in configurations and pricing, automating repetitive processes, and shortening the sales cycle. It also improves efficiency by integrating with other systems, reducing the need for rework or delays caused by miscommunication.

Industries with complex, customizable products, such as automotive, industrial equipment, electronics, and aerospace, benefit significantly from CPQ. It is particularly valuable for sectors that require tailored solutions, like manufacturing and engineering.

CPQ integrates with ERP systems to access real-time inventory, pricing, and production data, and with CRM systems to leverage customer information for personalized quoting. This seamless integration ensures consistency across sales, production, and customer management.

Key features to look for include robust product configuration capabilities, pricing flexibility with rule-based models, integration with ERP/CRM systems, automation for quote generation, and a user-friendly interface. Analytics and reporting tools for tracking performance and customer insights are also highly beneficial.